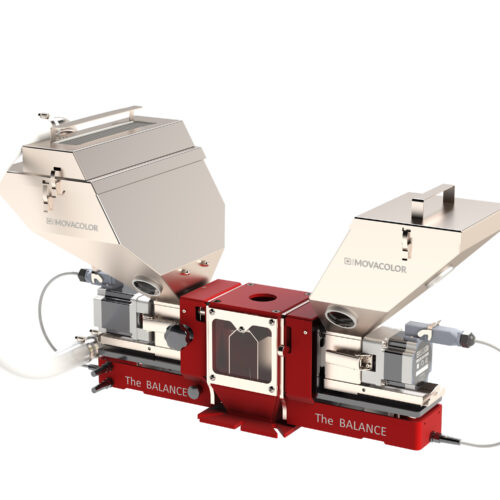

Dosing rejects and sprues in the form of regrind can result in saving substantial amounts of colorant. The secret? Dosing masterbatch, powder, liquid or another additive and regrind simultaneously.Read more

High accuracy

Equiped with proven Movacolor dosing technology which gives you full control over your material input.