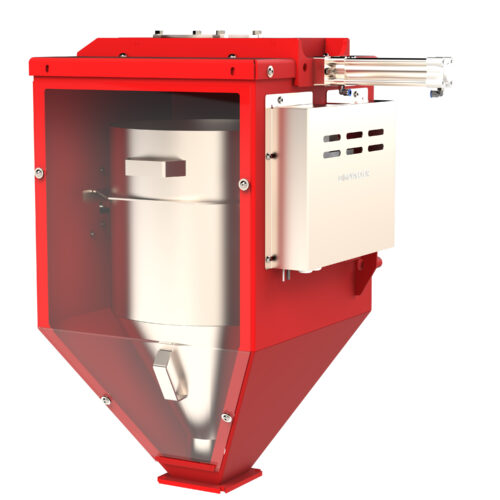

The MMS Weight is specially designed to measure the actual feed capacity of an extruder.Read more

Intuitive design

Out-of-the-box installation: Start working more efficiently quickly. This unit is easy to install and supplied pre-configured. Can be operated without extensive training together with the MCTouchscreen controller.